Want to get a beautiful yet affordable interior door for your house? Before buying it, there are several factors to consider and give it a thought. This article will discuss door core quality in detail and talk about different kinds of doors.

Solid wood doors have continued their legacy in the last century for being the ‘number one’ choice for homes. But recently, they are no longer the priority of interior designers. As innovations took place, the hollow core and the solid core became more popular. By the first look, interior passage doors and wood exterior doors seem quite similar as they are built wholly by solid wood. But that’s not the case every time; some doors look like solid wood doors, but they are made by construction techniques that make them seem like that, but they are not.

There are three types of wood doors employed in construction: solid wood, hollow core, and solid core. The construction methods for each door are different, and therefore, each of them has distinct advantages and disadvantages. It’s entirely your decision to prioritize some advantages over disadvantages. No single wood door will serve for all purposes.

Solid Wood Doors

- Entirely made up of wood

- Frame-and-panel structure (not a single slab)

- Can be used as an interior or exterior doors

- Possess traditional looks

Frame and panel or solid wood slab construction techniques are used for manufacturing solid wood doors. They usually need natural wood like pine, oak, or maple. For exterior doors, you can use solid wood construction for maximum strength that guarantees security. You may rely on cheaper solutions for interior doors.

All of the solid wood doors are made up of 100% natural wood (except hardware and accessories.) Some solid wood doors can be constructed of unified or single wood slabs. But the usual technique of building single wood doors is frame-and-panel. Some wood species are great sound-blockers, but some may not do it efficiently. Softwoods are poor sound-blockers, while hardwoods (oak, maple, etc.) can effectively block the rooms' sound transmission.

The wood panel door seems to be made up of one single piece of wood. But in reality, it’s not. The six-panel door is not new and has been a traditional asset in houses for centuries, constructed of stiles, rails, and mullions. After painting the door with aesthetic colors and contours, it looks like one solid piece of wood.

Pros

- Good Strength

- Rigid and Solid

- Good Soundproofing

- Resistant against Fire

- Increases Resale Value of the House

Cons

- Relatively Expensive

- Expansion, Contraction, and Warping with Time

Solid wood doors are an excellent choice for interior and exterior doors. Just keep that in mind that wood should be finished or painted if used for exterior doors.

Hollow-Core Doors

- Outside Wood Shell or Paperboard with Plastic Core

- Used for Interior Doors Only

- Very Common in New Houses

Made with a slightly thin wood layer or fiberboard stacked over honeycombed cardboard, hollow-core doors are among the finest and cheapest doors available in the market. Interior passage doors are often made up of hollow-core due to their inexpensiveness.

Medium-sized Production houses prefer making hollow-core doors as they have so many advantages. Most importantly, they are very inexpensive. They can easily be moved due to their lightweight, and it's almost effortless to swing them. Easy installation can save you several bucks from unnecessary spending. A typical house may have more than a dozen interior doors. Therefore, hollow-core doors seem to be the most economical solution.

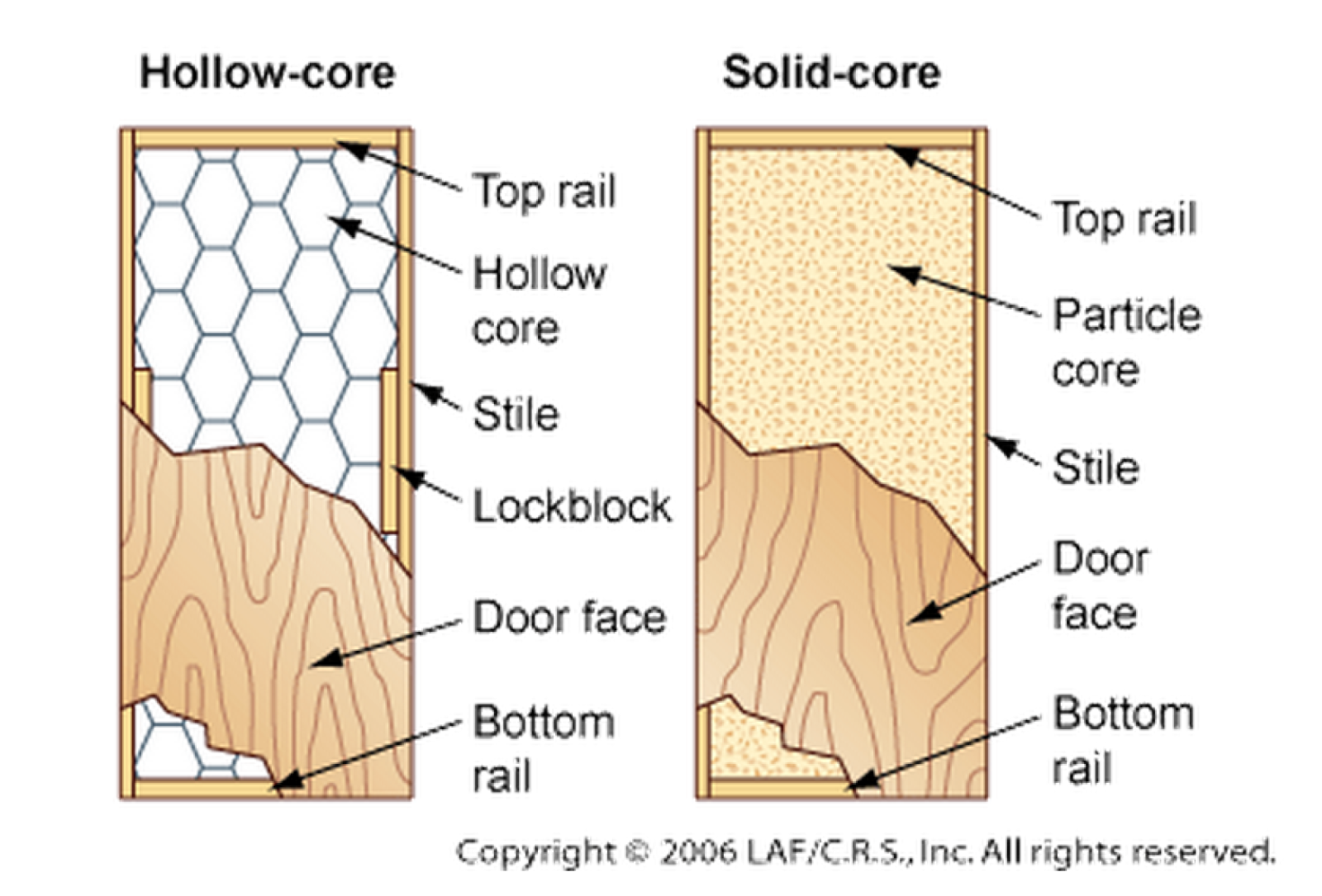

You might think of them as hollow because of their name, but they aren’t literally hollow. Its name might be misleading as they have a honeycombed core inside with a solid wood surface over which wood veneer is glued. Because of the frame and honeycomb core, the door becomes somewhat rigid and provides a little soundproofing ability. Due to the empty space inside the door, its name has become hollow-core.

The hollow-core doors are often criticized due to their strength and quality. Still, they are part of every other house because they provide a cheap interior door solution. By installing hollow-core doors in bathrooms, kitchens, storerooms, and bedrooms, you’re saving a big chunk of money that can be used in other house upgrades.

Pros

- Low Cost

- Easy and Quick Installation

- Lightweight

- Stable with almost no warping

Cons

- Ineffective Soundproofing

- Ineffective Fireproofing

- Low Strength

- Wood and Veneers Exposed Edges

Solid-Core Doors

- Made up of Engineered wood core and natural wood veneer

- Used for Interior and Exterior Purposes

- Available in Fire-resistant Feature as Mineral Core Doors

A solid engineered wood such as fiber wood or Masonite is used along with a fine-grade surface wood veneer glued over the solid surface. This is an interim construction method used by the door designers. Solid-core doors work well for both interior and exterior gates.

Solid-core wood doors actually have features of both hollow-core and solid wood doors. It’s the composite of both doors that has wood veneers glued over engineered or composite wood. Although they are not so expensive, they can still offer strong resistance as exterior doors. Even some solid wood doors are weaker than solid-core doors.

Because of their affordability, some house designers prefer them over solid wood doors. They have excellent soundproofing and fire-resistance virtues when the thickness is kept at least 1 ¾ inches. Because of their hardened rigidity, they are immune to expansion and contraction because of humidity.

Some solid-core doors may not use veneer surfaces if the designer wants to give them a painted wood look. For that, MDF or any other engineered wood will be shaped and molded to provide an appearance that resembles the frame-and-panel door.

Pros

- Good Soundproofing

- Moderately Expensive

- Adequate Fire Resistance

- No Warping Effect

Cons

- Design Options are Limited (In Comparison to Solid Wood)

- Difficult Installation Process

- Heavy Weight

No comments:

Post a Comment